As Apple released its new products featuring Mini LED panel, the mini LED backlight application have become the focus of the LED industry.

Mini LED backlight displays have high brightness and high contrast ratios, which can reach up to 1,000,000:1, compared to the 10,000:1 contrast ratios of current mainstream displays. The key technology to improve contrast and resolution is “local dimming”. Due to the smaller mini LED size compare to current LEDs, it can be separated hundreds to thousands of dimming zones and the more the number of dimming zones of the backlight, the more detailed picture can be presented.

On the topic of the color effect, OLED display used to perform better than current LCD display. However, the new generation white mini LED featuring KSF phosphor can perform equally as good as OLED. KSF is a narrow-band red-emitting phosphor which can deliver a wider color gamut coverage up to 95%. ProLight’s mini LED adopts KSF phosphor which improves color saturation and cost-efficiency, and can avoid the OLED burn mark problem.

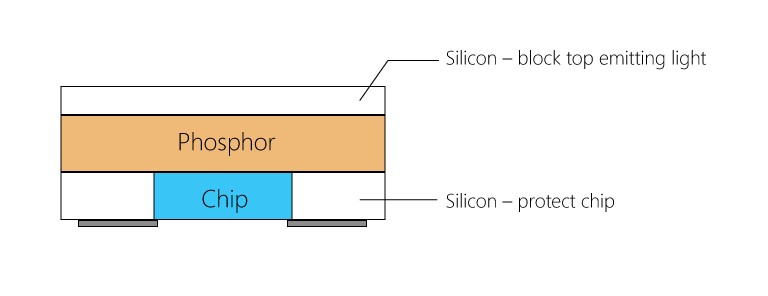

Despite the benefits mentioned, KSF phosphor actually is not resistant to humidity, therefore, one of the improvements required for better packaging technology will be to improve reliability. ProLight Opto have a unique packaging technology by cooperating with a material manufacturer in Japan to develop a special air-tight material, which can seal the chip and phosphor to improve reliability and also maintain its brightness.