Due to price pressure in the LED market, most of the multi-color in 1 PLCC packaging adopts Epoxy to be the encapsulation material. However, Epoxy has poor heat resistance and yellowing easily, also the material can produce huge stress on gold wire for it to broke. Thus the reliability using epoxy material is poor for outdoor application.

On the other hand, silicon material is a better material to be used for outdoor application, but production process for it to be used in PLCC package is much more difficult and it is more expensive than epoxy. To solve the production difficulties, ProLight have developed a new Nano-material to be the adhesive between PLCC and silicon, this Nano-material can enhance adhesion to avoid silicon peeling and provide longer LED life. Silicon material has good humidity and high temperature resistance, and with its air-tightness characteristic, it can protect LED chip from moisture. Furthermore, silicon has an elastic characteristic, which can protect gold wire from breaking from stress and is suitable for harsh outdoor application.

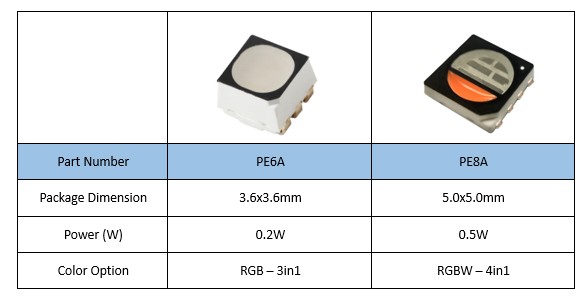

ProLight have applied this Nano-material tech on the PLCC LED series for 3-in-1 and 4-in-1. These LED series have withstood 1000 cycle of thermal shock.

More information